A tank eductor, also known as a tank mixing nozzle or jet pump, is a device used to effectively mix liquids within a tank without any moving parts. Its operation is based on Bernoulli's Principle and the Venturi effect.

Here's a brief explanation of how it works:

- Motive Fluid Inlet: A high-pressure fluid (called the "motive fluid") is pumped into the eductor. This can be liquid recirculated from the tank or a new liquid being introduced.

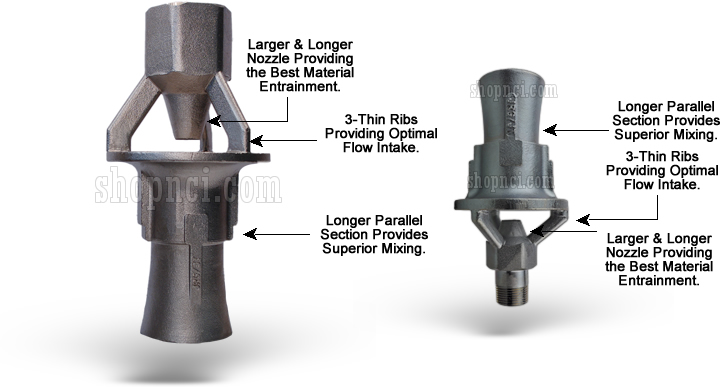

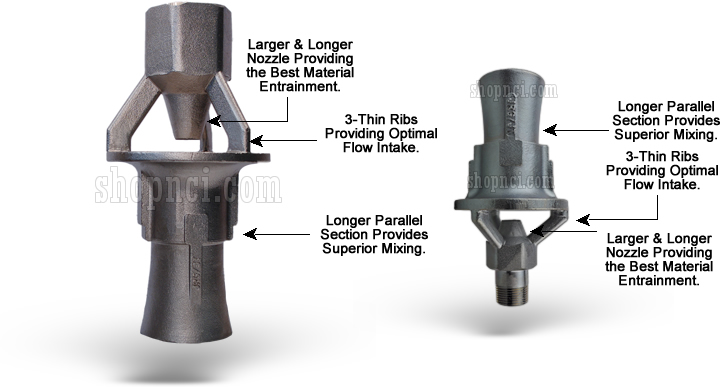

- Nozzle and Velocity Increase: The motive fluid passes through a converging nozzle inside the eductor. As the fluid is forced through this narrower opening, its velocity significantly increases, and its pressure simultaneously decreases (Bernoulli's Principle).

- Low-Pressure Zone (Venturi Effect): This high-velocity, low-pressure jet creates a suction or vacuum effect in the surrounding area within the eductor's mixing chamber.

- Entrainment of Tank Contents: The lower pressure inside the eductor draws in the surrounding liquid from the tank (the "suction fluid") into the mixing chamber.

- Mixing and Discharge: The motive fluid and the entrained tank liquid are intimately mixed within the eductor. This mixture is then discharged back into the tank at a higher volume and with considerable force, creating turbulence and promoting thorough mixing throughout the tank.

Essentially, the eductor uses the energy of a pumped fluid to entrain and mix a much larger volume of the tank's contents, providing efficient agitation, preventing stratification, and ensuring uniform distribution of substances.